WT1200-2S

WT1300-2S

WT1500-2S

WT1600-2S

2-layer air bubble film machine (single extruder)

Introduction:

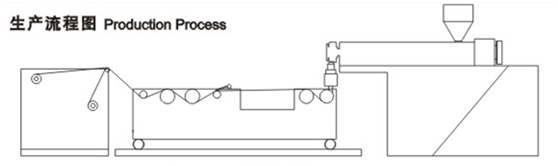

1. Main parts: Extruder, Control Panel, Bubble forming section, Winder;

2. To produce 2 layers air bubble film (bubble layer + base layer);

3. Film width from 1,000mm to 3,000mm;

4. Screw L/D ratio is 1:30, it adopts special mixing function and high plasticizing capacity design, with good plasticization, good mixing effect and high output;

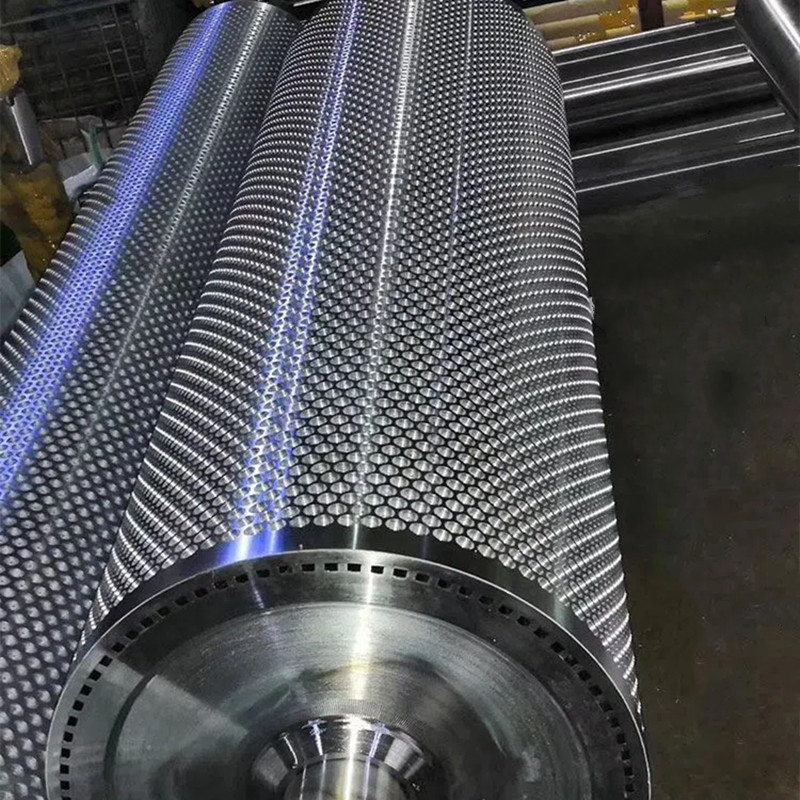

5. The bubble forming cylinder adopts special internal circulation chilled water design to ensure perfect bubble forming effect under high speed operation.

Mechanical Transmission Diagram & Bubble Structure:

Main Technical Variables:

|

Model |

WT1200 2S |

WT-1500-2S |

WT-1600-2S |

WT-2000-2S |

|

Diameter of Screw Stem |

φ65 mm |

φ65 mm |

φ75 mm |

φ75 mm |

|

L/D Ratio of Screw |

30:1 |

30:1 |

30:1 |

30:1 |

|

Material of Scerw & Barrel |

38 CrMoALA |

38 CrMoALA |

38 CrMoALA |

38 CrMoALA |

|

Width of T-die Head |

1350 mm |

1450 mm |

1650 mm |

1750 mm |

|

Heating Way |

Casting-aluminum heating device |

Casting-aluminum heating device |

Casting-aluminum heating device |

Casting-aluminum heating device |

|

Width of Bubble Roller |

1280 mm |

1280 mm |

1580 mm |

1680 mm |

|

Width of Products |

1200 mm |

1300 mm |

1500 mm |

1600 mm |

|

Thickness |

0. 06-0. 25 mm |

0. 06-0. 25 mm |

0. 06-0.25 mm |

0. 06-0.25 mm |

|

Main Motor |

15 kw |

15 kw |

18.5 kw |

18.5 kw |

|

Tractiong Motor |

1.5 kw |

1.5 kw |

1.5 kw*2 |

1.5 kw*2 |

|

Total Power |

58 kw |

58 kw |

70 kw |

70 kw |

|

Rewinder |

Turnover duplex turret rewinding type |

Turnover duplex turret rewinding type |

Turnover duplex turret rewinding type |

Turnover duplex turret rewinding type |

|

Max. Output |

70 kg/h |

70 kg/h |

90 kg/h |

90 kg/h |

|

Linear Speed |

1000 m/h |

1000 m/h |

1000 m/h |

1000 m/h |